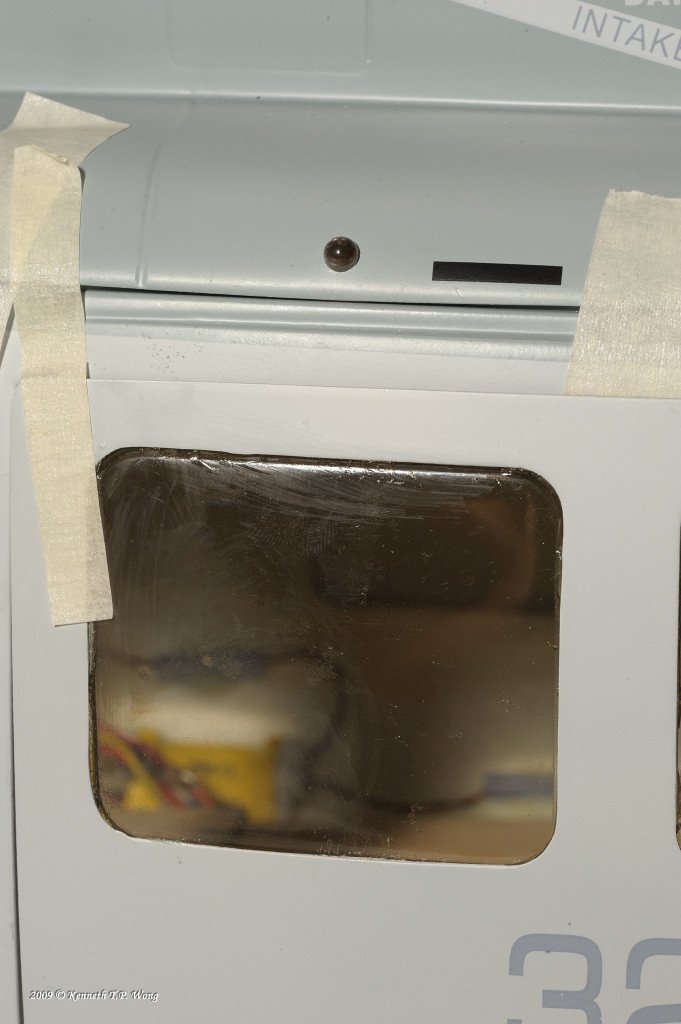

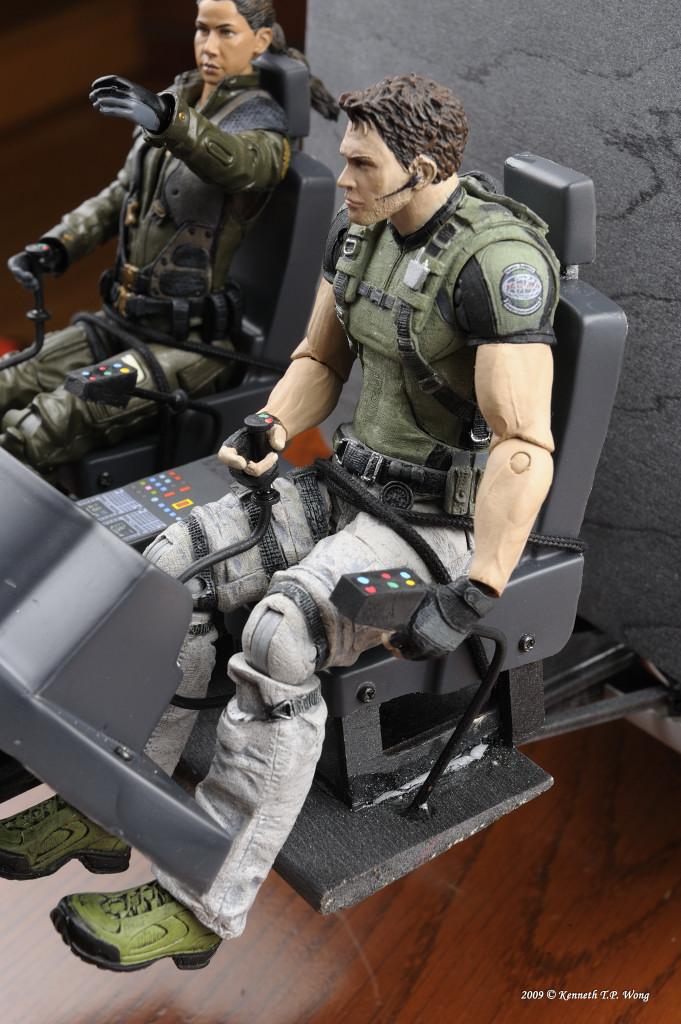

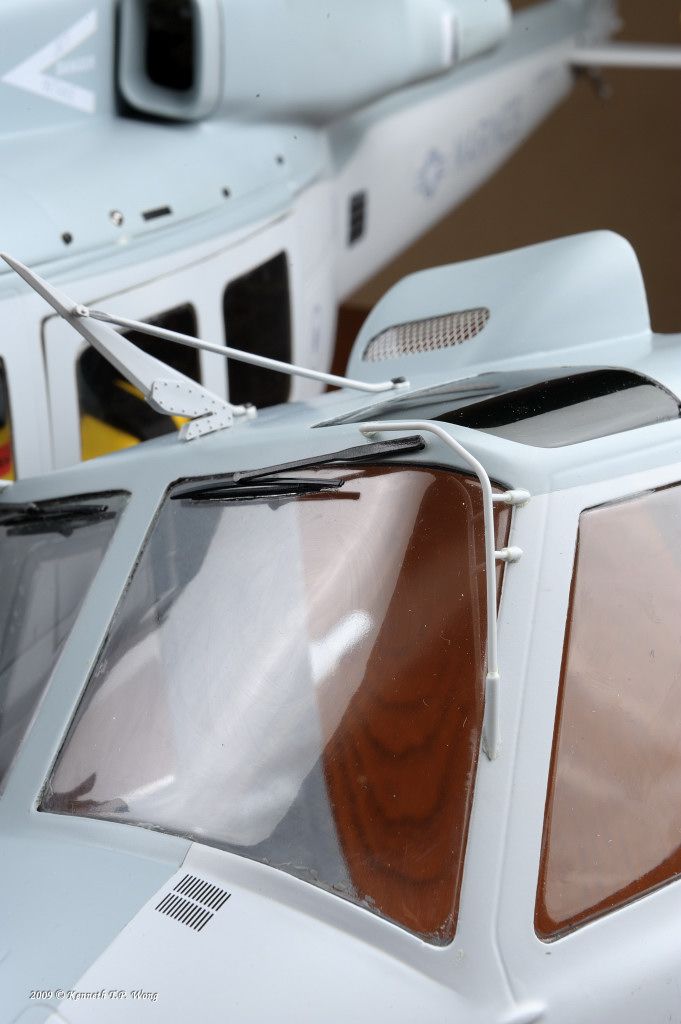

I'm pretty new to RC Heli's, but like all new hobbies, one goes a little overboard. Although I have put a few Pod-and-Booms into fuselages, this is the first time I'm spending more time to make it 'nicer'. Don't mind all the messy epoxy and other unslightly things, still learning.

I'll break the build down into sections, but to start, this is my present fleet after selling nearly all my Beams except for one.

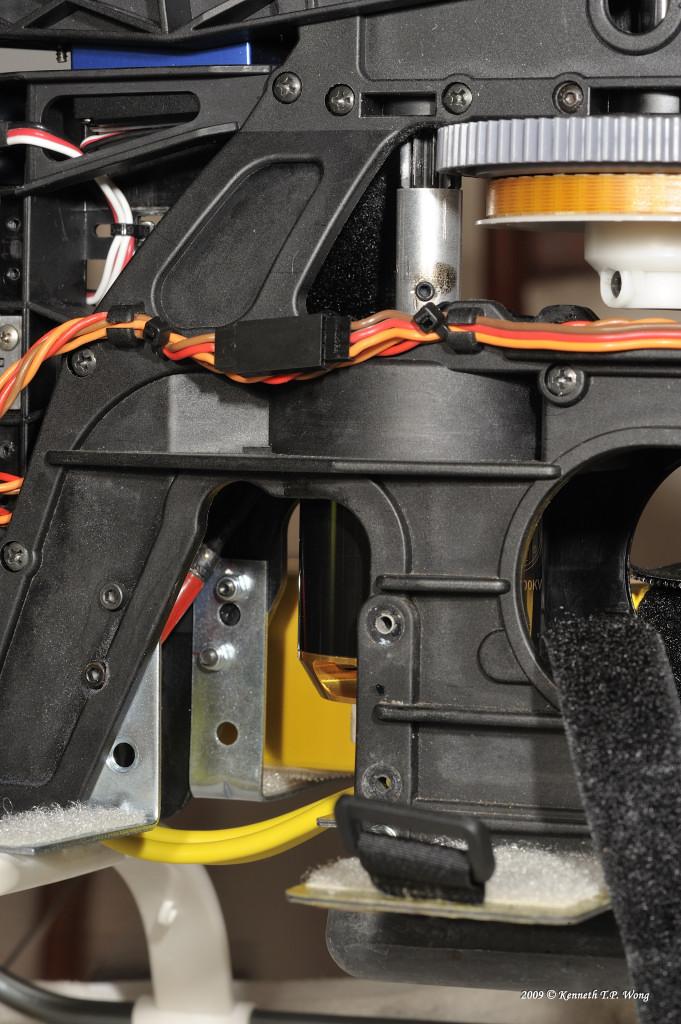

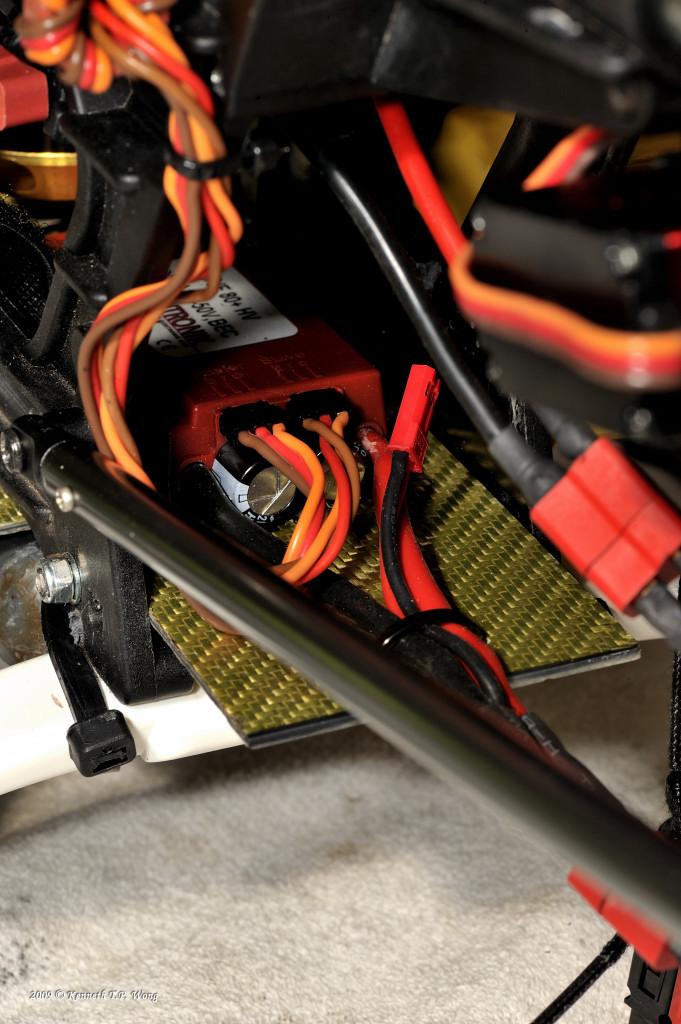

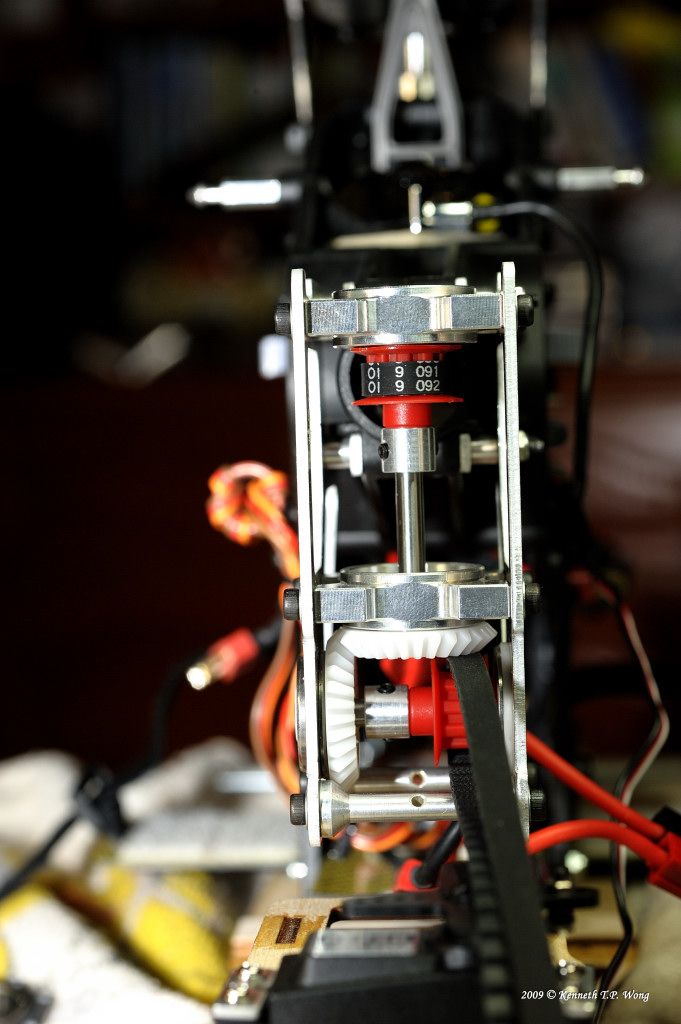

I'll be using a second hand Raptor 50 (don't know which model but definitely not the SE, but it's a V2 I think) that has been converted to electric.

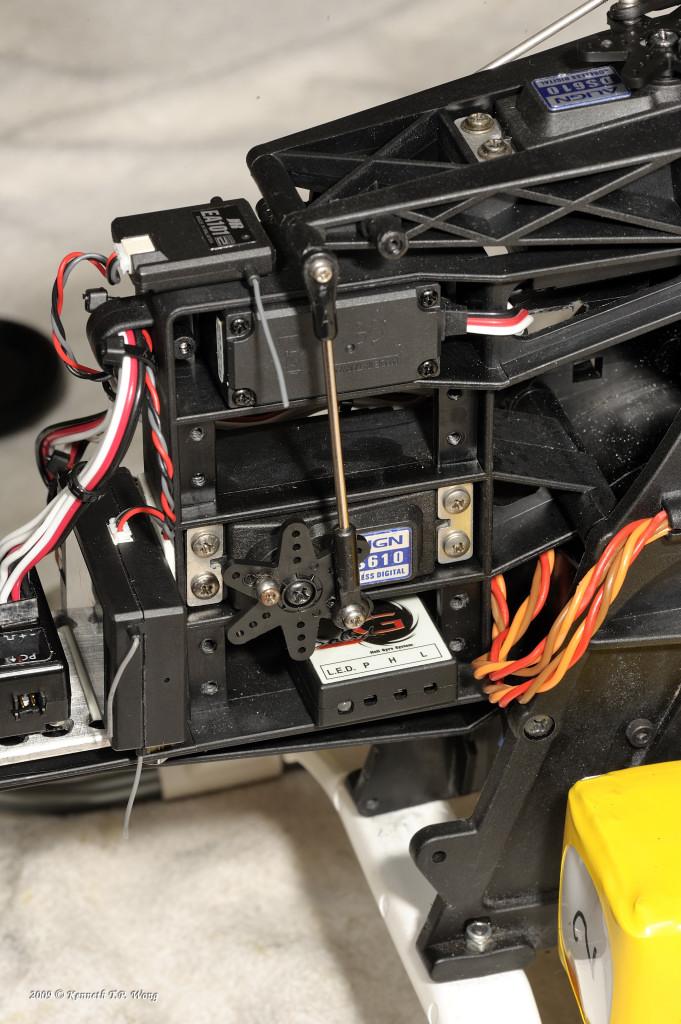

Motor: Scorpion 4035-400

ESC: Kontronics Jive 80+HV

Cyclic Servos: Align DS610

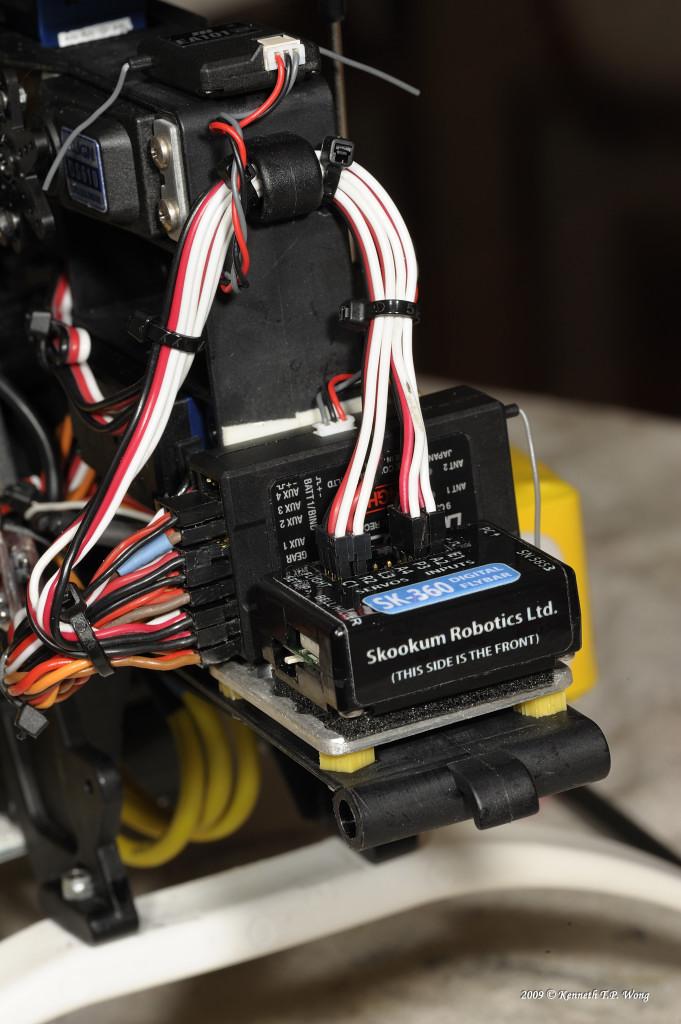

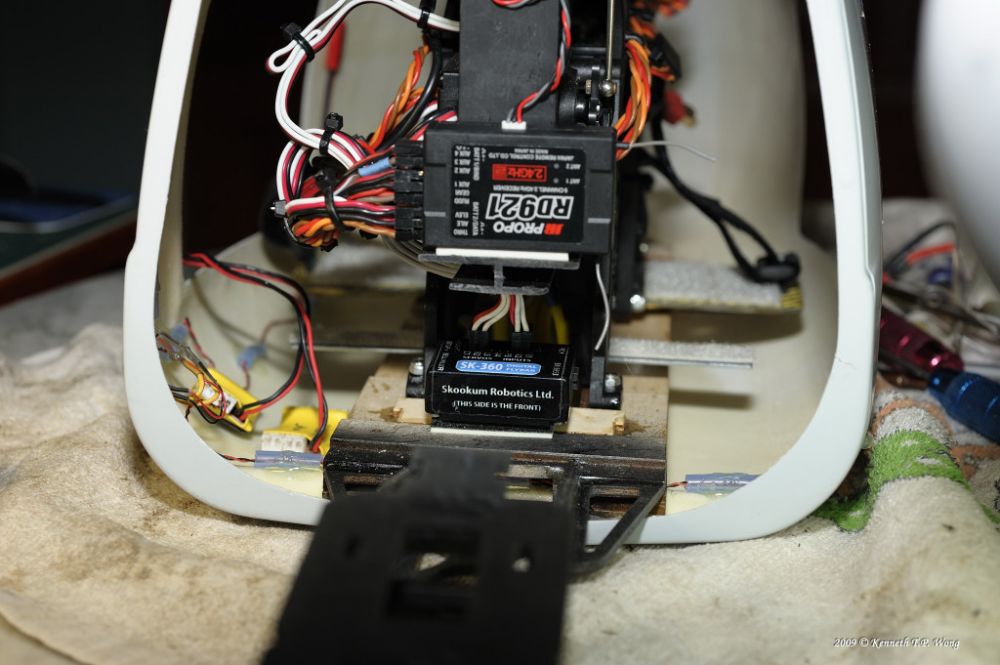

Stablization: Skookum SK360

Tail Gyro: CYB Solid G

Tail Servo: JR8900

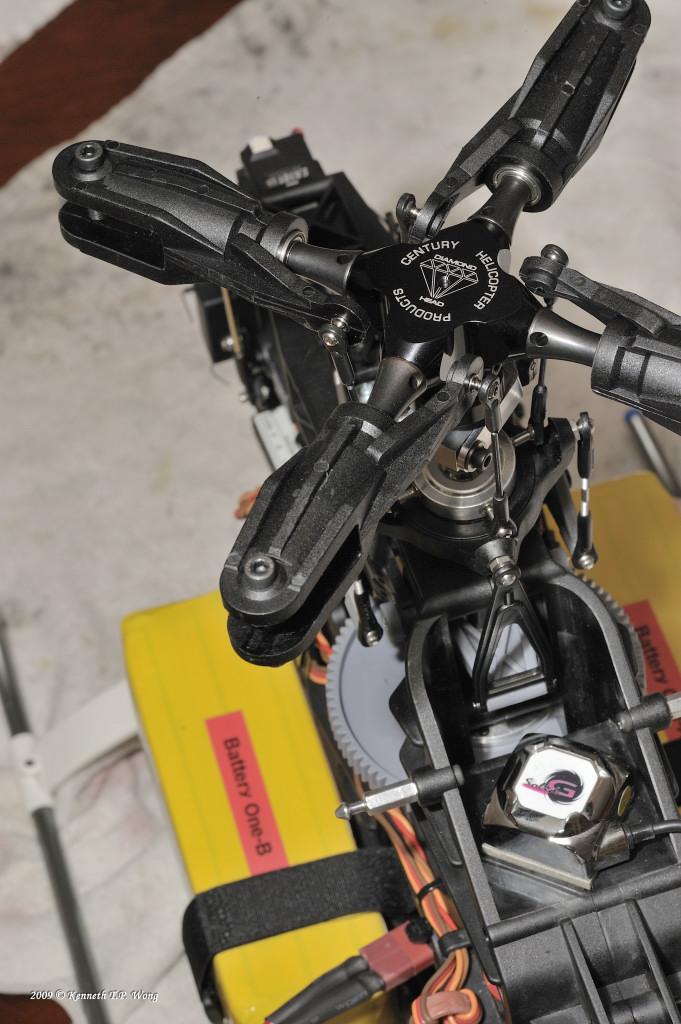

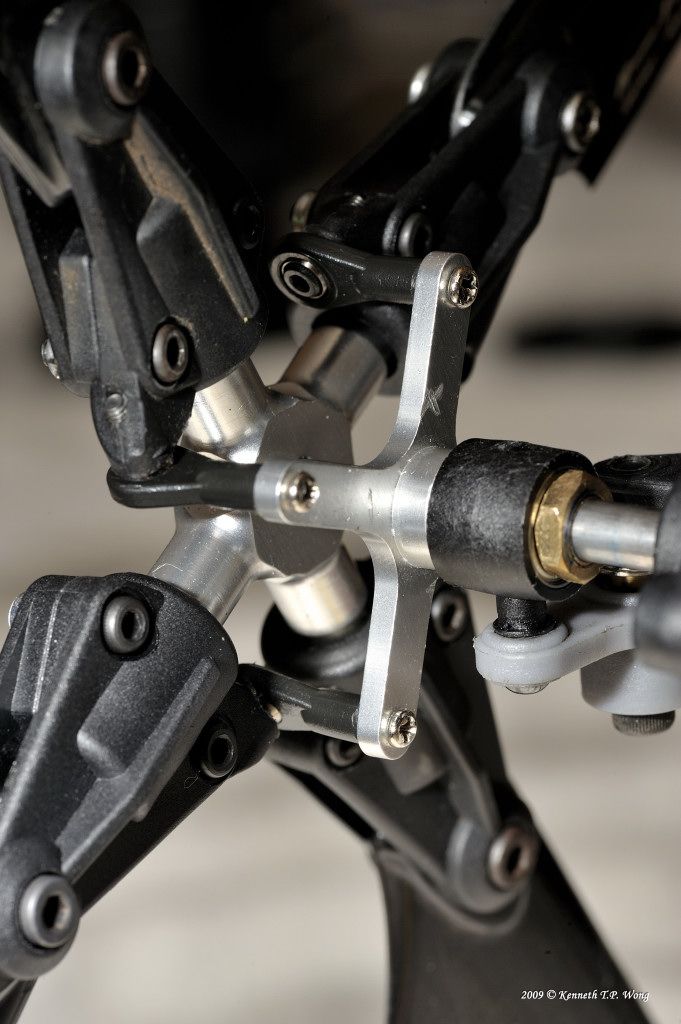

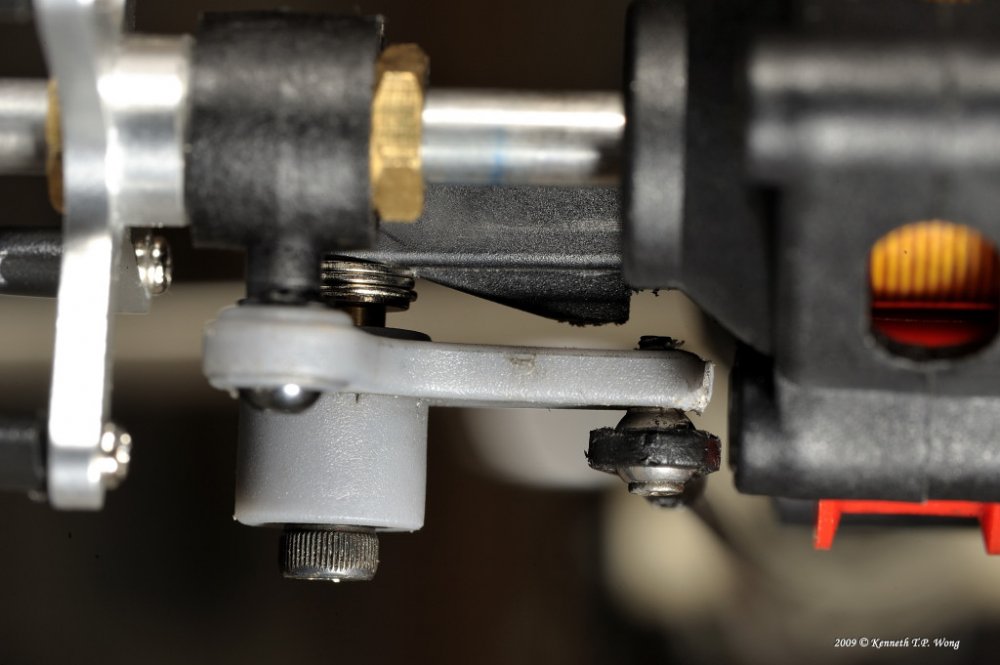

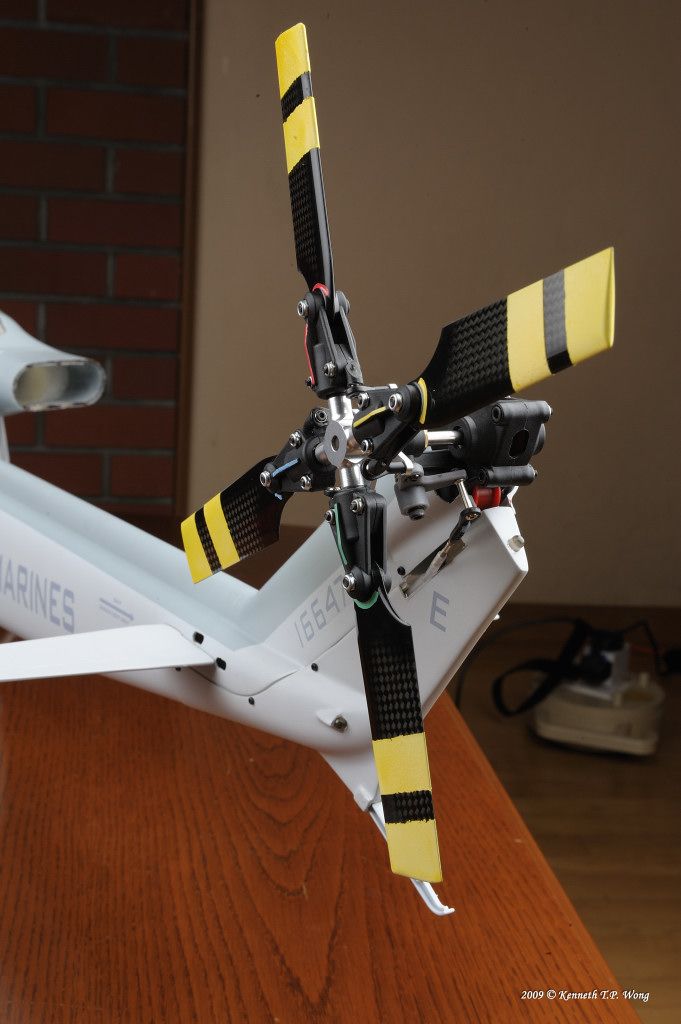

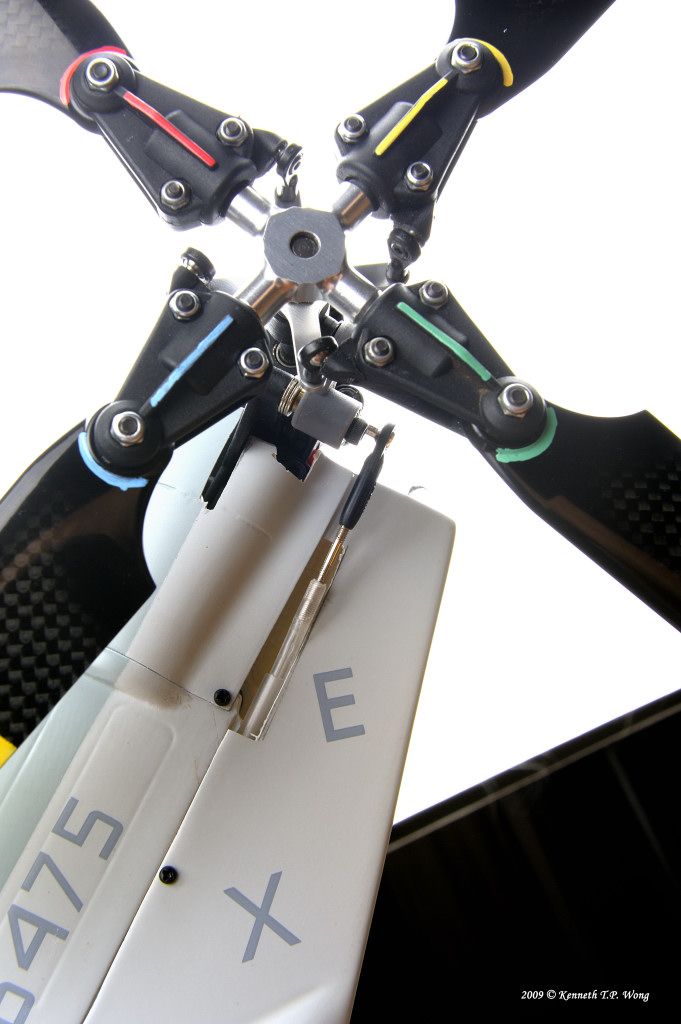

4-Blade Head: Century

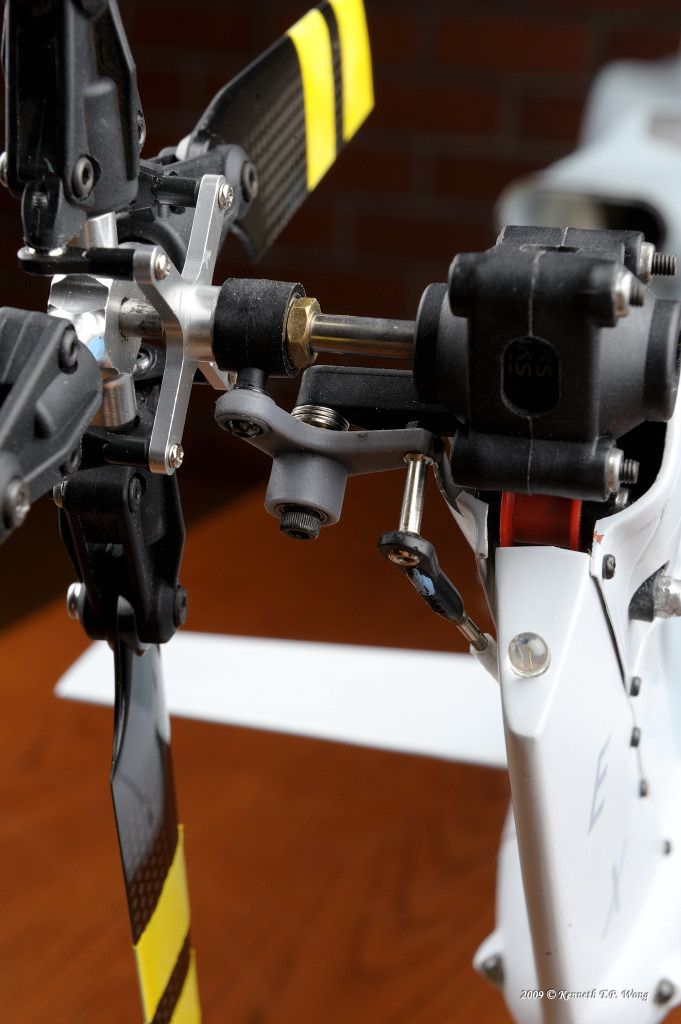

4-Blade Tail: Century

Battery Power: 10S or 12S (still testing)

Main rotor will spin CCW and tail will be on the left.

I'll break the build down into sections, but to start, this is my present fleet after selling nearly all my Beams except for one.

I'll be using a second hand Raptor 50 (don't know which model but definitely not the SE, but it's a V2 I think) that has been converted to electric.

Motor: Scorpion 4035-400

ESC: Kontronics Jive 80+HV

Cyclic Servos: Align DS610

Stablization: Skookum SK360

Tail Gyro: CYB Solid G

Tail Servo: JR8900

4-Blade Head: Century

4-Blade Tail: Century

Battery Power: 10S or 12S (still testing)

Main rotor will spin CCW and tail will be on the left.

Comment