Hi Fellow Fliers!

Here is the scratch built foamy semi-scale war birds thread as promised. After our success with constructing RC planes with Depron and blue foam, we decided to create something more interesting. Adrian took on the Curtiss P-40 KittyHawk, while I tackled the Focke Wulf 190 D9. This will be a general description of what we did as there are too many details to cover. Both planes are powered by the MINI AC1215/20 using the TMM1812 ESCs. GWS 1:5 gearbox is used. Both planes weighed below 400gms with battery.

The materials for construction are 6mm Depron and 1inch Blue foam purchased from Art Friend at Bras Basah.

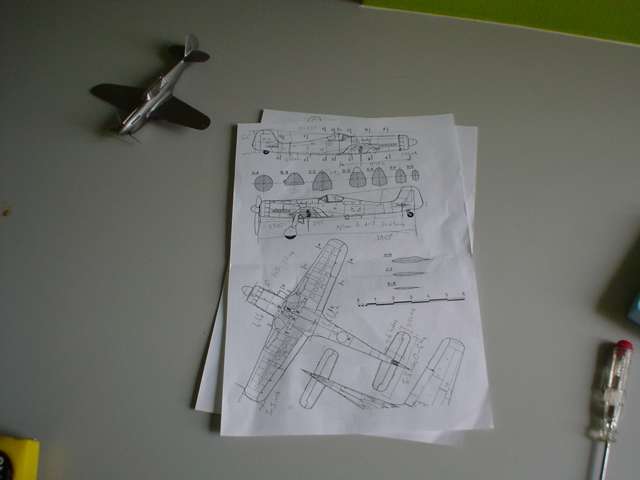

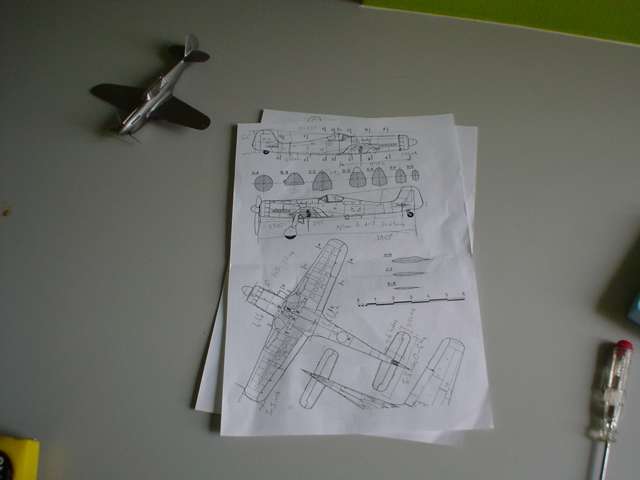

After deciding which planes to build, the first thing we got was 3 view drawings

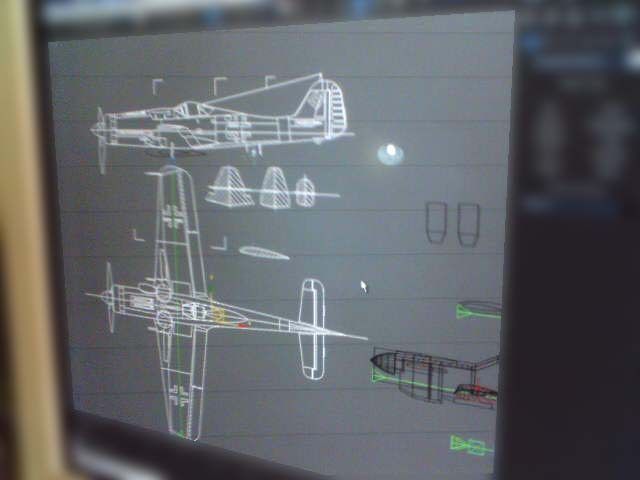

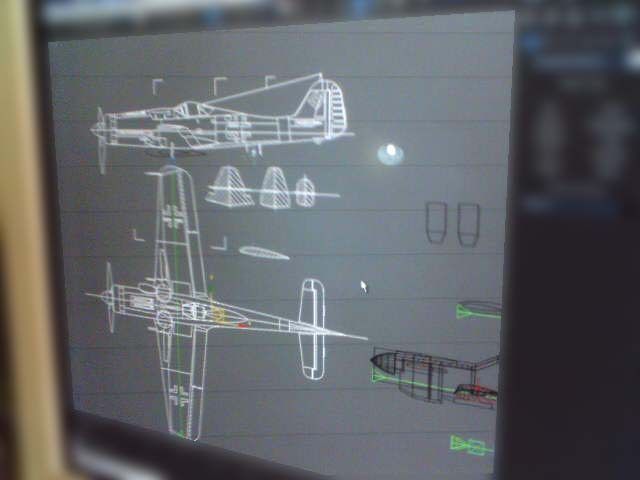

of our desired War bird. You can get excellent blue prints from this site www.suurland.com . If you have a drafting program, you can use the computer to design your plane.

of our desired War bird. You can get excellent blue prints from this site www.suurland.com . If you have a drafting program, you can use the computer to design your plane.  Spending some time to design and preview your plane on the computer is a great way to plot your construction strategy. We aimed to keep our planes below 30 inches (below 73cm) wingspan.

Spending some time to design and preview your plane on the computer is a great way to plot your construction strategy. We aimed to keep our planes below 30 inches (below 73cm) wingspan.

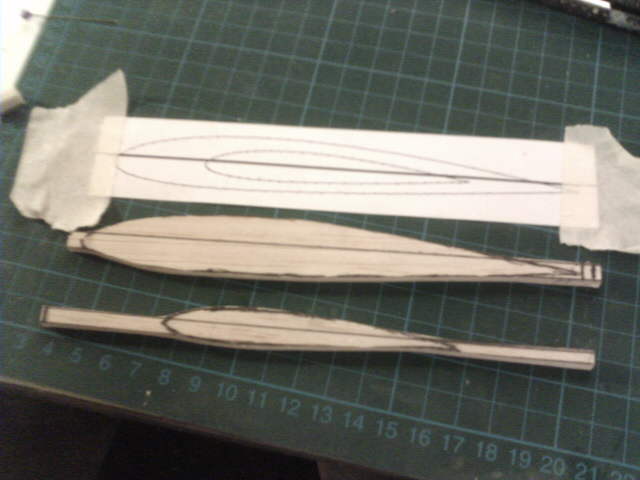

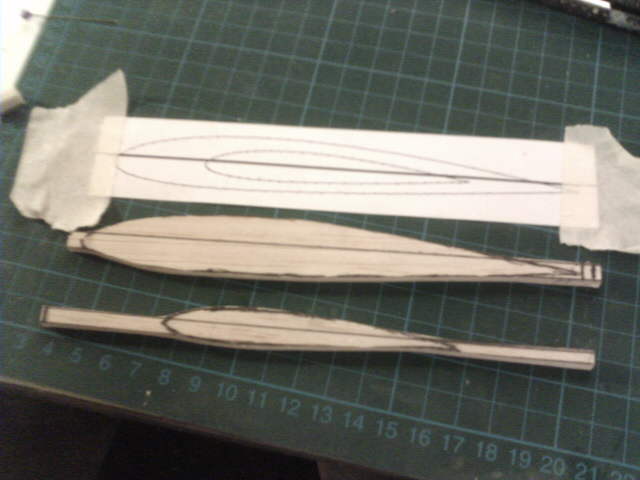

The wings are constructed using Blue foam using the hot wire cutting method. For the airfoil we used the real airfoil of the P-40 with minimal changes. After drawing them on the computer, we printed it out at the scale we want and plotted the shape on 5mm hard balsa wood. The wood templates are then shaped and the edges are glued with aluminum foil.

The wood templates are then shaped and the edges are glued with aluminum foil.  The foil is to prevent hot wire from burning into the wood. Aircraft grade thin plywood can be used but will take more time to shape. The templates are then pinned

The foil is to prevent hot wire from burning into the wood. Aircraft grade thin plywood can be used but will take more time to shape. The templates are then pinned  to the prepared Blue Foam blocks and cut with the hot wire. (For hotwire cutting tips, please refer to this thread .) After cutting the wings (below image shows a bad cut and good cut)

to the prepared Blue Foam blocks and cut with the hot wire. (For hotwire cutting tips, please refer to this thread .) After cutting the wings (below image shows a bad cut and good cut) , the wings are trimmed and gradually sanded to shape.

, the wings are trimmed and gradually sanded to shape.

They are reinforced with a thin strip of carbon fibre and epoxied together

They are reinforced with a thin strip of carbon fibre and epoxied together  . Give the wings dihedral if needed for your design.

. Give the wings dihedral if needed for your design.

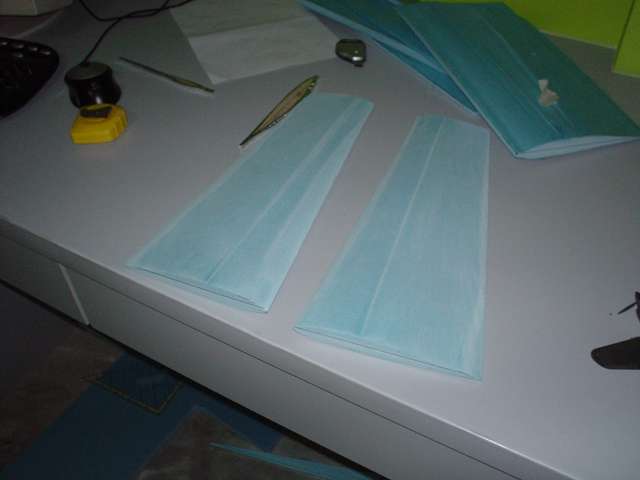

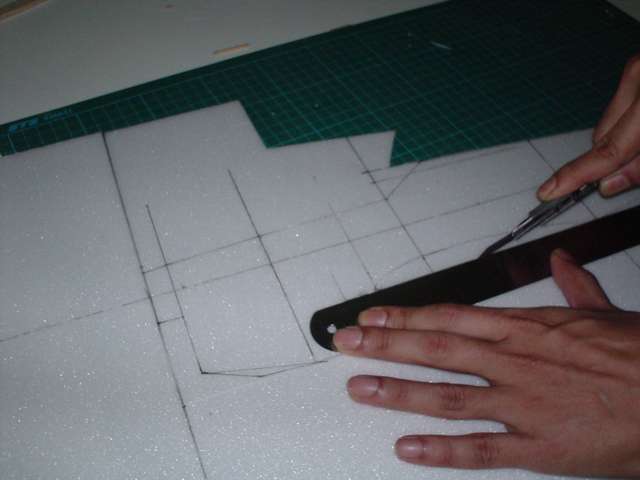

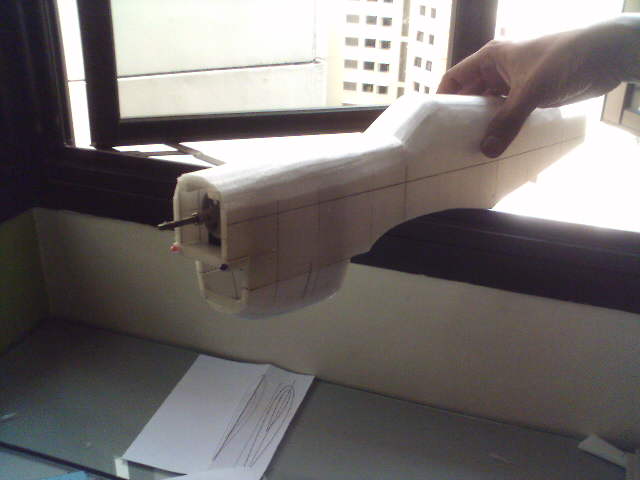

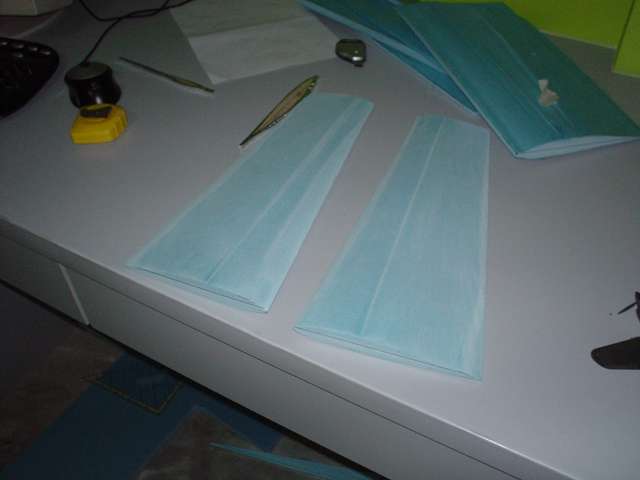

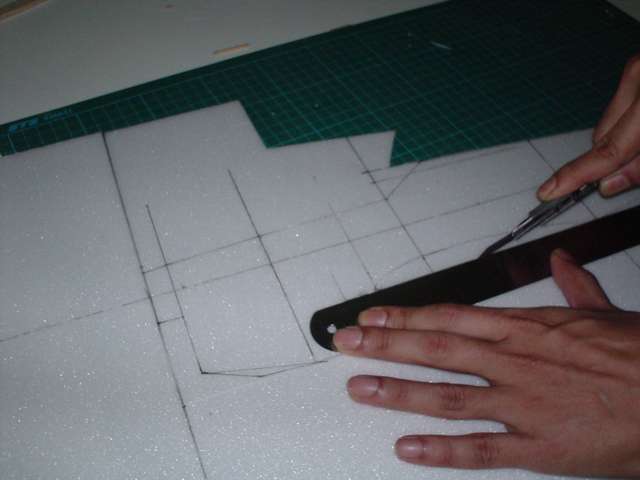

Next the 6mm Depron is prepared for fuselage construction . The Depron is marked and cut. Then they are glued together with 5 minute epoxy

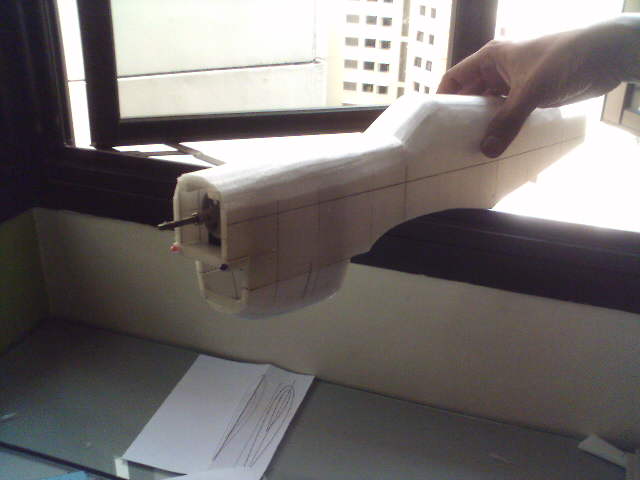

. The Depron is marked and cut. Then they are glued together with 5 minute epoxy  . The motor mount is made of blue foam with a slot cut into it and a hard wood block for the motor mount glued in the slot. Give about 2 degrees right side thrust. Reinforcement bulkheads are added where strength is required.

. The motor mount is made of blue foam with a slot cut into it and a hard wood block for the motor mount glued in the slot. Give about 2 degrees right side thrust. Reinforcement bulkheads are added where strength is required.  They also act as separating compartments for your battery, servos and radio receiver.

They also act as separating compartments for your battery, servos and radio receiver.

Once the glue has set, the fuselage can be shaped further with a knife blade and sand papered until they are refined.

with a knife blade and sand papered until they are refined.  The stabilizer, fin and tail moving surfaces are prepared and hinge slots cut.

The stabilizer, fin and tail moving surfaces are prepared and hinge slots cut.

Ailerons are cut and prepared on the wings, hinges glued and all. Motor access cowling and hatch cut.

.

.

Final assembly; servos installed on the wings and zeroed. Wings then glued permanently to the fuselage. Servos, Pushrods, Radio receiver and horns installed.

The planes are now ready for painting. I used the Pelikan Casein based craft paints (Available at Sembawang book store) and Tamiya model paints to paint my aircraft and I strongly recommend the Pelikan paints as they are way easier to apply on foam. Tamiya acrylic paints will need several layers but it gives a nice matt finish.

Flight report.

My first flight was a disaster! I was too confident of hand launching the plane myself but screwed it up! Luckily the damage was easily reparable and 3 hours later, I maidened my plane successfully. Unfortunately, I didn’t take any video or pictures of my plane in flight, but I will be taking some in future flights. From the crash, we learnt that we need to reinforce the fuselage near the wing area as it is quite weak. The main cause of the crash is pilot error; I should have used more power during the launch and get an assistant to help me launch it. After repairs, the 2nd flight was fabulous! I must say this is by far the best flying low wing plane I’ve constructed.

Adrian is luckier and his first flight was a resounding success! Refer to the video gallery for his plane in action.

Hope this will inspire you guys to build your own Foamy planes!

The Proud Owners!

Adrian and his P40

Me and my FW190

Here is the scratch built foamy semi-scale war birds thread as promised. After our success with constructing RC planes with Depron and blue foam, we decided to create something more interesting. Adrian took on the Curtiss P-40 KittyHawk, while I tackled the Focke Wulf 190 D9. This will be a general description of what we did as there are too many details to cover. Both planes are powered by the MINI AC1215/20 using the TMM1812 ESCs. GWS 1:5 gearbox is used. Both planes weighed below 400gms with battery.

The materials for construction are 6mm Depron and 1inch Blue foam purchased from Art Friend at Bras Basah.

After deciding which planes to build, the first thing we got was 3 view drawings

of our desired War bird. You can get excellent blue prints from this site www.suurland.com . If you have a drafting program, you can use the computer to design your plane.

of our desired War bird. You can get excellent blue prints from this site www.suurland.com . If you have a drafting program, you can use the computer to design your plane.  Spending some time to design and preview your plane on the computer is a great way to plot your construction strategy. We aimed to keep our planes below 30 inches (below 73cm) wingspan.

Spending some time to design and preview your plane on the computer is a great way to plot your construction strategy. We aimed to keep our planes below 30 inches (below 73cm) wingspan. The wings are constructed using Blue foam using the hot wire cutting method. For the airfoil we used the real airfoil of the P-40 with minimal changes. After drawing them on the computer, we printed it out at the scale we want and plotted the shape on 5mm hard balsa wood.

The wood templates are then shaped and the edges are glued with aluminum foil.

The wood templates are then shaped and the edges are glued with aluminum foil.  The foil is to prevent hot wire from burning into the wood. Aircraft grade thin plywood can be used but will take more time to shape. The templates are then pinned

The foil is to prevent hot wire from burning into the wood. Aircraft grade thin plywood can be used but will take more time to shape. The templates are then pinned  to the prepared Blue Foam blocks and cut with the hot wire. (For hotwire cutting tips, please refer to this thread .) After cutting the wings (below image shows a bad cut and good cut)

to the prepared Blue Foam blocks and cut with the hot wire. (For hotwire cutting tips, please refer to this thread .) After cutting the wings (below image shows a bad cut and good cut) , the wings are trimmed and gradually sanded to shape.

, the wings are trimmed and gradually sanded to shape.

They are reinforced with a thin strip of carbon fibre and epoxied together

They are reinforced with a thin strip of carbon fibre and epoxied together  . Give the wings dihedral if needed for your design.

. Give the wings dihedral if needed for your design. Next the 6mm Depron is prepared for fuselage construction

. The Depron is marked and cut. Then they are glued together with 5 minute epoxy

. The Depron is marked and cut. Then they are glued together with 5 minute epoxy  . The motor mount is made of blue foam with a slot cut into it and a hard wood block for the motor mount glued in the slot. Give about 2 degrees right side thrust. Reinforcement bulkheads are added where strength is required.

. The motor mount is made of blue foam with a slot cut into it and a hard wood block for the motor mount glued in the slot. Give about 2 degrees right side thrust. Reinforcement bulkheads are added where strength is required.  They also act as separating compartments for your battery, servos and radio receiver.

They also act as separating compartments for your battery, servos and radio receiver.Once the glue has set, the fuselage can be shaped further

with a knife blade and sand papered until they are refined.

with a knife blade and sand papered until they are refined.  The stabilizer, fin and tail moving surfaces are prepared and hinge slots cut.

The stabilizer, fin and tail moving surfaces are prepared and hinge slots cut.

Ailerons are cut and prepared on the wings, hinges glued and all. Motor access cowling and hatch cut.

.

.

Final assembly; servos installed on the wings and zeroed. Wings then glued permanently to the fuselage. Servos, Pushrods, Radio receiver and horns installed.

The planes are now ready for painting. I used the Pelikan Casein based craft paints (Available at Sembawang book store) and Tamiya model paints to paint my aircraft and I strongly recommend the Pelikan paints as they are way easier to apply on foam. Tamiya acrylic paints will need several layers but it gives a nice matt finish.

Flight report.

My first flight was a disaster! I was too confident of hand launching the plane myself but screwed it up! Luckily the damage was easily reparable and 3 hours later, I maidened my plane successfully. Unfortunately, I didn’t take any video or pictures of my plane in flight, but I will be taking some in future flights. From the crash, we learnt that we need to reinforce the fuselage near the wing area as it is quite weak. The main cause of the crash is pilot error; I should have used more power during the launch and get an assistant to help me launch it. After repairs, the 2nd flight was fabulous! I must say this is by far the best flying low wing plane I’ve constructed.

Adrian is luckier and his first flight was a resounding success! Refer to the video gallery for his plane in action.

Hope this will inspire you guys to build your own Foamy planes!

The Proud Owners!

Adrian and his P40

Me and my FW190

especially the p40 !

especially the p40 !

Comment